Filling Orders

When it comes to filling orders, the goal is to complete them as efficiently as possible while correctly managing each customer’s expectations. However, this can be complicated. Every order goes through multiple phases and each phase requires a different team. There is a lot of opportunity for confusion that causes delay or inaccurate timeline estimates. In addition, the more teams there are the more difficult team workload management is.

Team Workload Management Across Multiple Phases and Teams

As an example, say that the sales team at a furniture design shop receives an order. After compiling all the info, they pass the this order to engineering. The order then moves on to production, painting and finally installation. While there is likely only one sales and engineering team, there may be multiple production, painting and installation teams. In order to help their teams fill orders efficiently and on time, the head of operations requires easy visibility into the status and timeline of each phase of each order as it happens. They also require clarity into the workload of each individual production, painting and installation team. Without this, they will end up overloading one team and giving another team too few orders. Priority Matrix helps both large and small companies accomplish this.

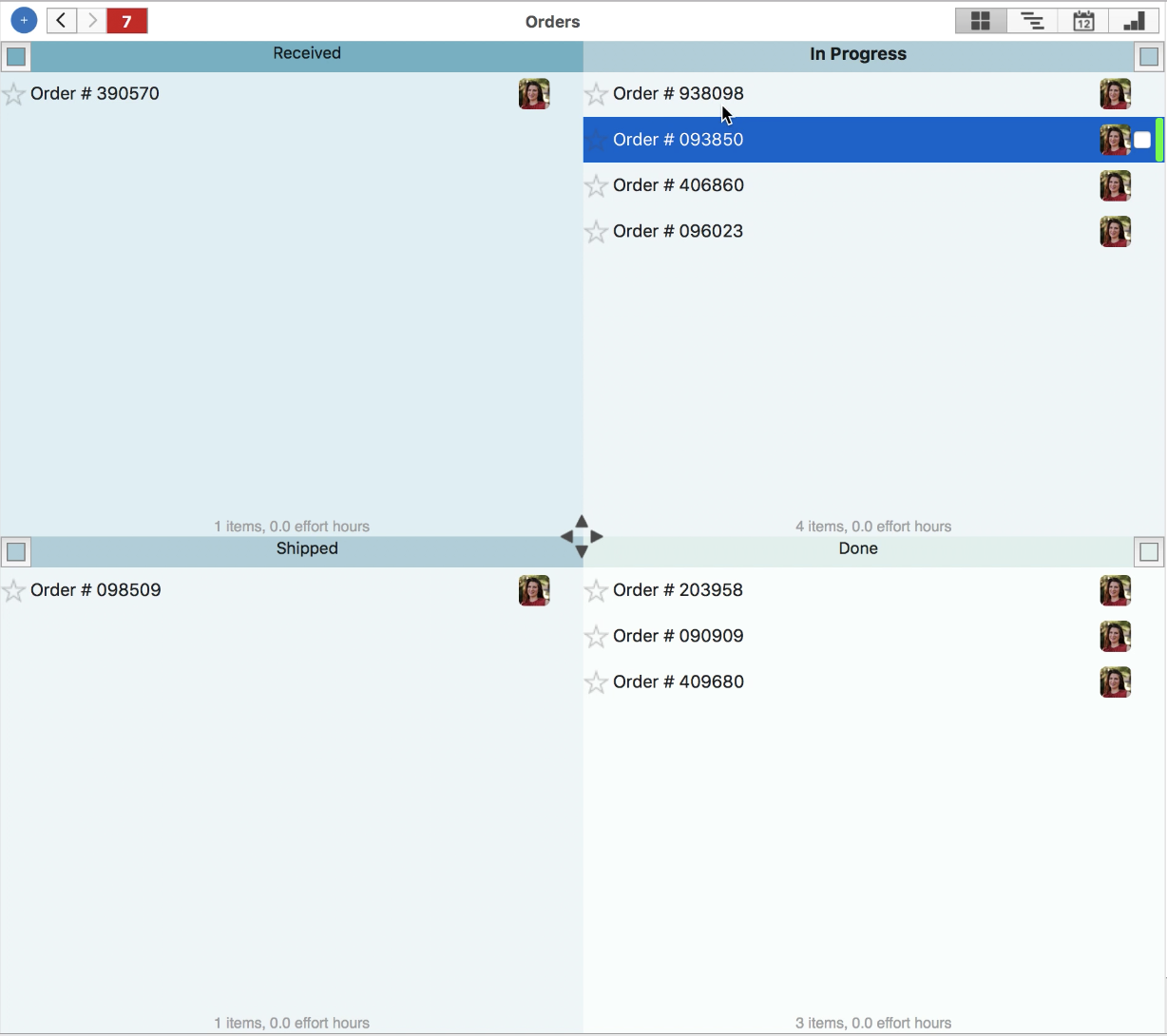

Managing All Orders

When the sales team receives an order, they will create an item with all relevant details in a project that holds all orders. When they send the order to the engineering team, the head of operations can move the correct item to the “In Progress” quadrant. In this way, all orders can be accounted for in only one view.

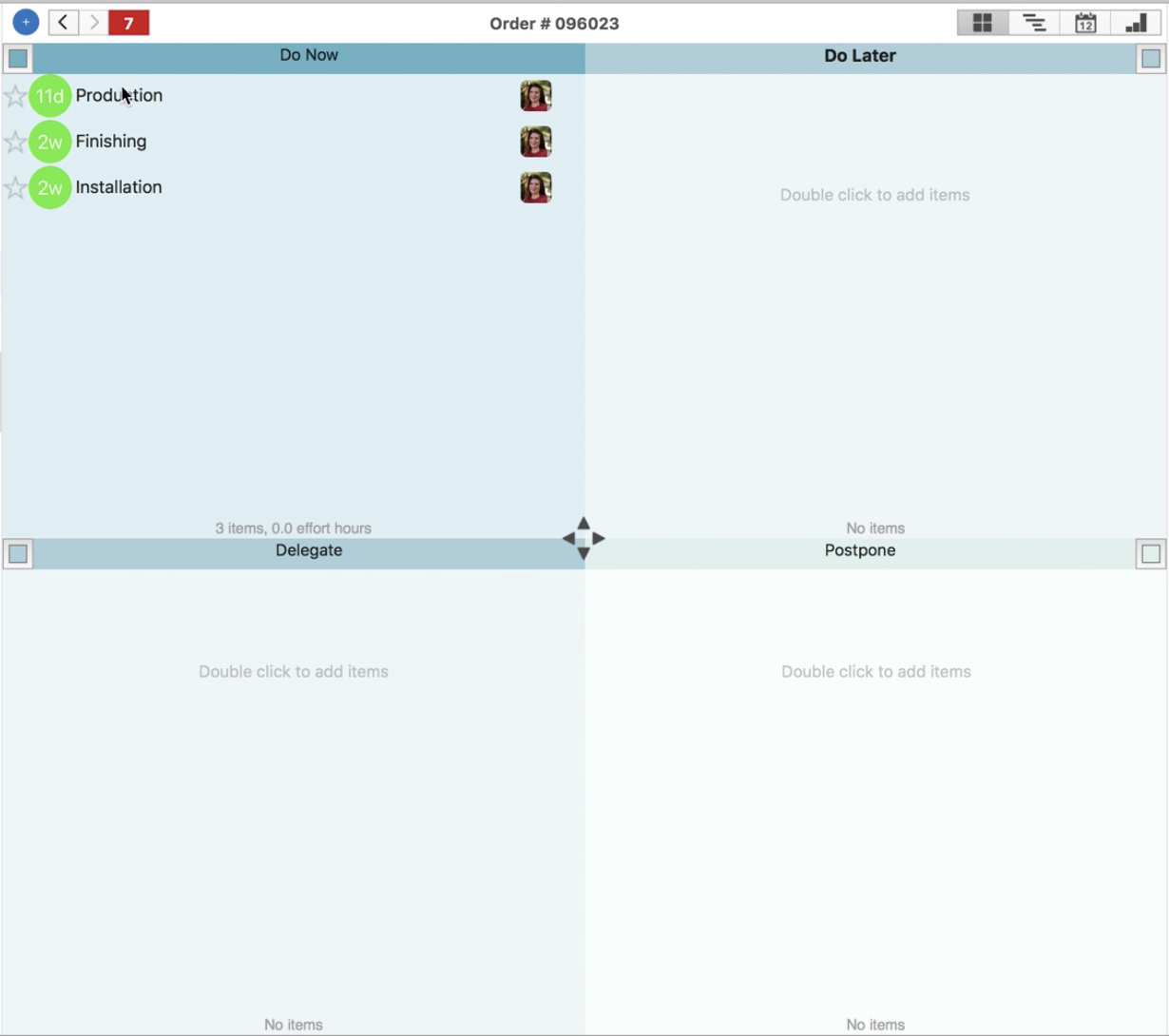

It is important to keep track of each individual phase that an order goes through. To help with this, the head of operations will create a project detailing each one of these phases:

As teams complete each phase, leads will mark the respective items complete. Because they can nest projects in Priority Matrix, it is easy for the head of operations to navigate from the project containing all orders to this individual order project. Simply double click on the order item and the nested project will open up.

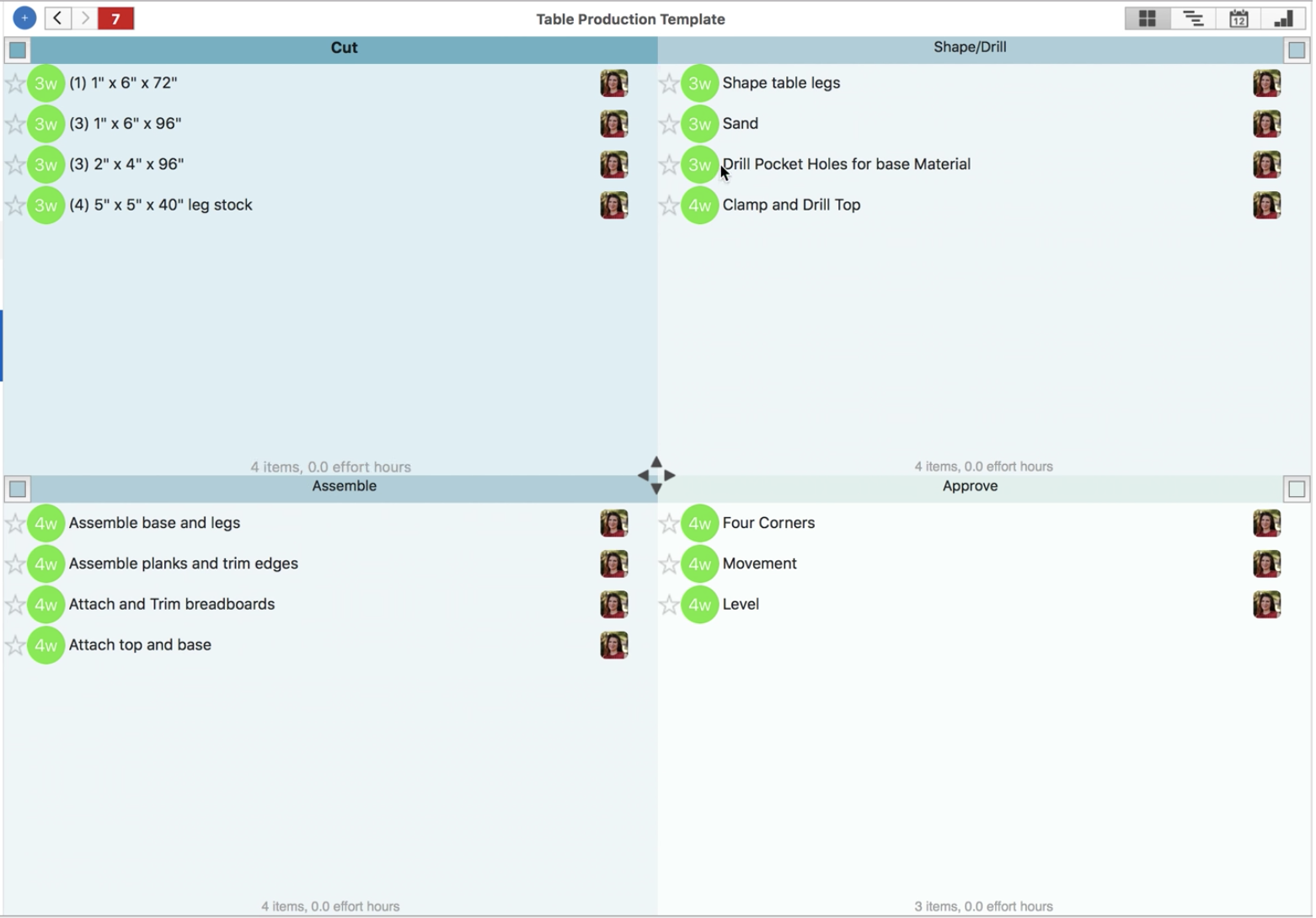

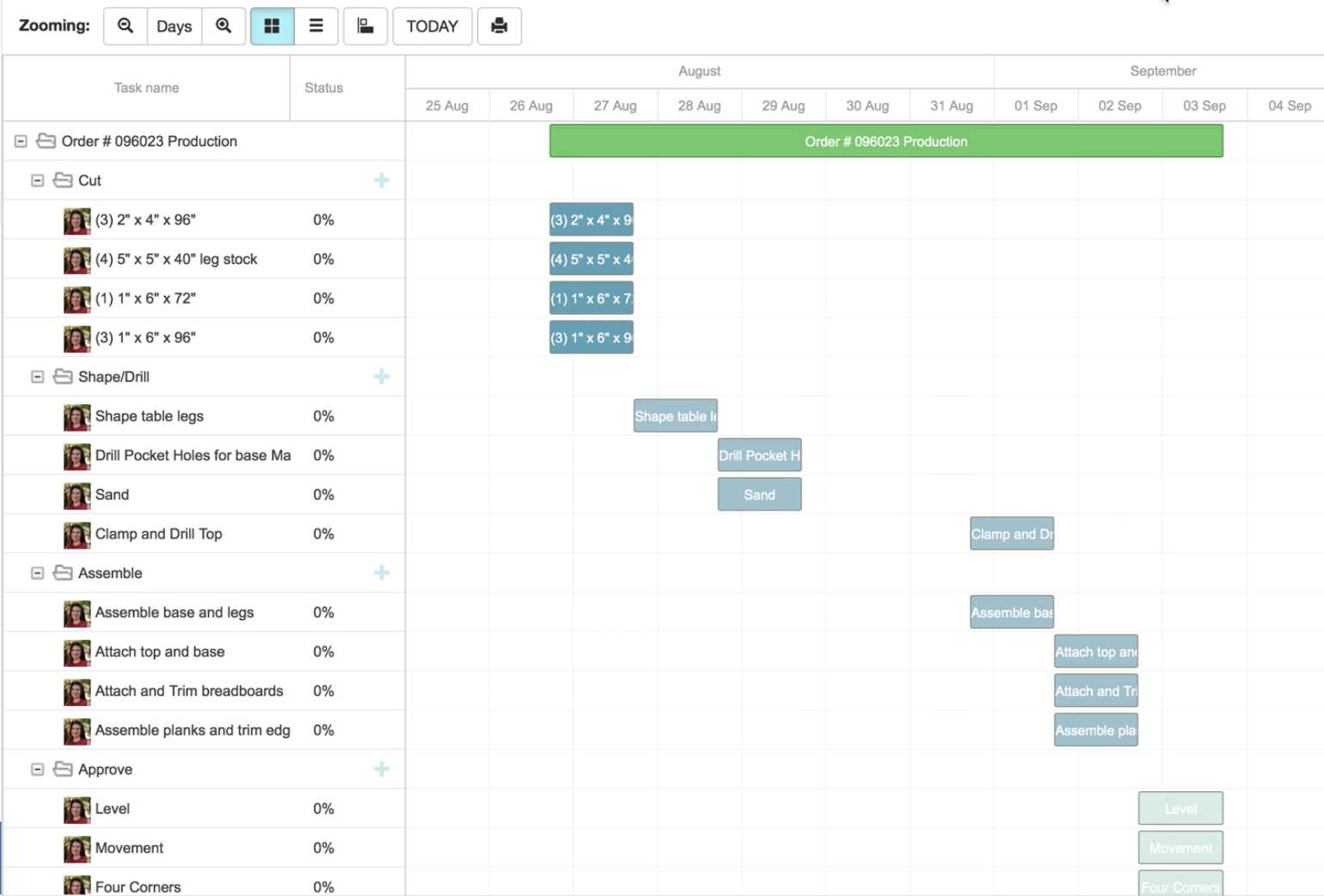

Preventing Extra Delay

If one of the order’s phases is delayed, it is important for everyone know the cause. By creating a project for each phase and once again nesting these phase projects in the individual order project, visibility around specific problems is improved. As an example, the “Table Production” project features as a checklists and status workbook for all the steps involved in the production of a particular type of table. If the head of operations looks at the order project above and sees that the production phase is overdue, they can once again navigate to the production project to see what the problem is.

If the team cannot drill pocket holes because the drill is broken, this is clear in the item details. In fact, because of the ease of communication around each task, the production lead will already have assign the “Drill Pocket Holes” item to the head of operations. They will have added extra comments letting them know the specifics so that the problem can be resolved.

Building Step Templates

While creating multiple projects for each order might seem like extra work, it really isn’t. It is easy to create and save custom templates for each type and phase of an order. This way, creating multiple projects takes a matter of seconds. As soon as the sales team receives a particular type of order and moves it into progress, management can use saved templates to create and nest each project needed. Any time that nesting these projects takes is well worth the ease of navigation later on.

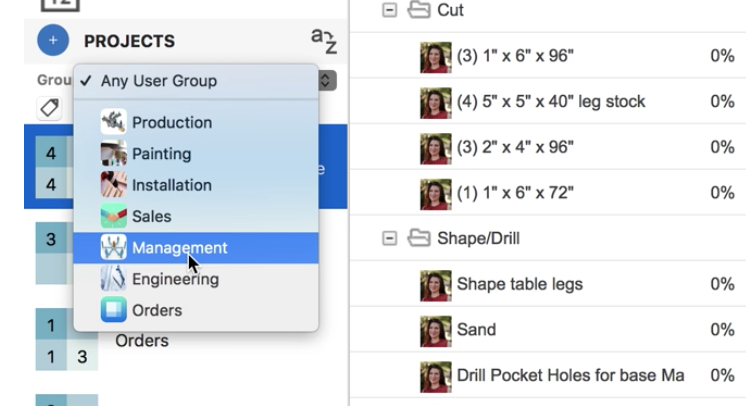

Team Workload Management With User Groups

When a new order comes in, it is easy to compare workloads across different teams. Priority Matrix user groups allows users to filter their view view based on the projects belonging to certain groups. This feature aids in comparing the workloads of “Production Team 1” and “Production Team 2.” Accurate team workload management like this ensures that each team is not overloaded but is doing as much as they are able.

Estimating Order Timeline Correctly

Saving due dates in a template keeps track of the increments of time between the project start and item due date. This way the calendar and gantt chart views can automatically reflect the length of a project:

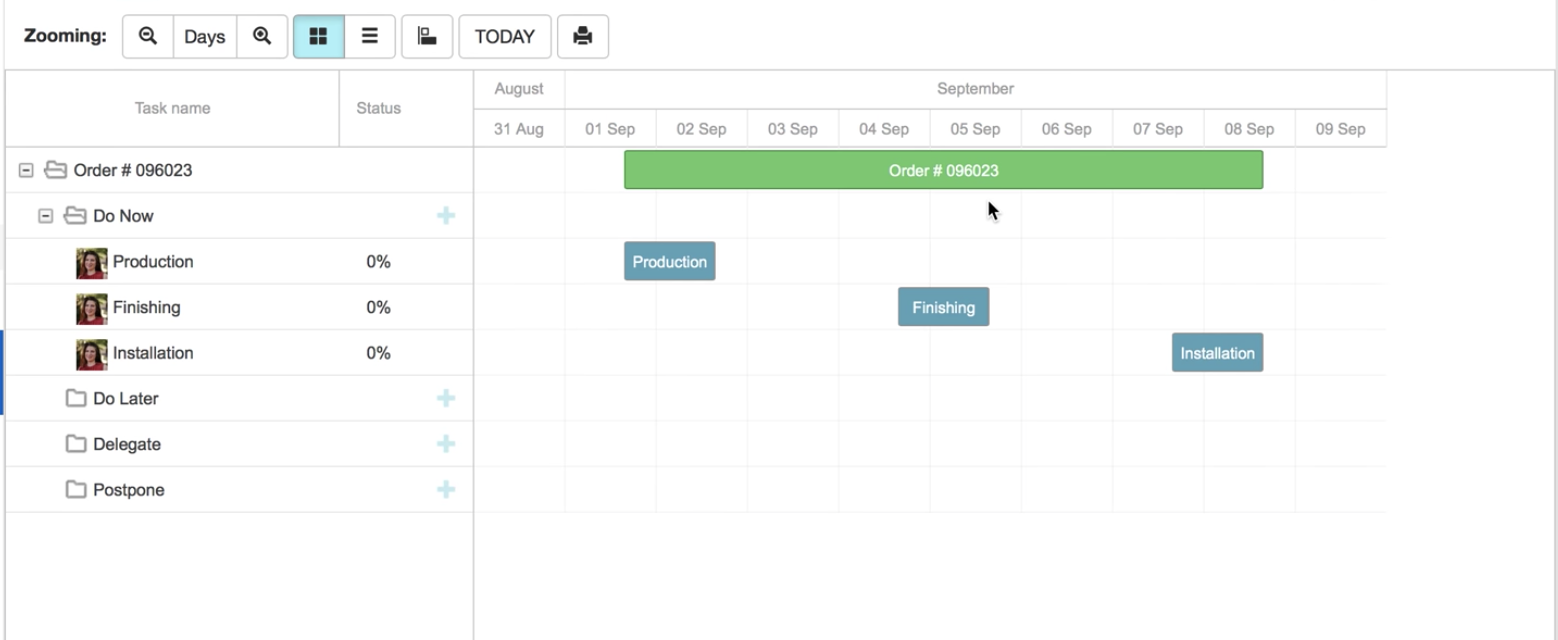

As an example, above, the gantt chart shows the overall timeline for the “Production,” “Finishing” and “Installation” phases. Below, the gantt chart shows the timeline for tasks in the “Production” of order #096023:

Video

To see order management, nesting, templates, user groups, and timelines in action, watch the video below: