Digital Manufacturing Requires Innovation, Starting With the Essentials

As with any important project, executive alignment is key for successful digital manufacturing transformation. However, old-fashioned communication and project management methods hold manufacturers back.

Transformed Collaboration, The First Step Towards Digital Manufacturing Success

McKinsey & Company’s 2018 digital manufacturing report shared that companies are struggling to break free of “pilot purgatory.” The report noted the importance of agile execution:

Manufacturing companies should drive execution of their Digital Manufacturing initiatives with an agile mindset across software and analytics. Beyond building the right external partnerships, they need to build the capability for internal collaboration across functions and break down organizational silos.

In addition, in “Six Key Factors That Make or Break a Manufacturer’s Digital Initiatives,” Stephen Engel, Senior Vice President at Hitachi Consulting, shared his thoughts on the topic. He said that leaders in manufacturing need to revamp their project management approach:

The traditional lecture-style monthly meetings and status reports don’t work in driving digital transformation. Instead, create an executive advisory board as a forum for education, and foster a roll-up-the-sleeves attitude about possibilities and approaches, taking care to ensure that all players are engaged as a team.

Monthly meetings and status reports are clearly not the answer. What then, can leaders in manufacturing do to prevent silos and confusion? The answer is digitized productivity methods. Update your practices using the suggestions below:

Modernizing Project Management for Digital Manufacturing

1. Emailing will not lead to Digital Manufacturing success

For many manufacturing executives, email is still the main way of communicating. This is a clear problem. Ineffective and old-fashioned communication should not be a contributing factor in stalled digital initiatives. There are many conversation tools to choose an alternative from . However, be aware that not all are improvements. Look for tools that allow more responsive communication, without loss of context.

2. Projects are physical entities

Projects as critical as those in digital manufacturing need more than a status spreadsheet. Innovation in project management is key. Tools that let teams visualize and engage with the whole project in one view are best. What’s more, solutions that integrate conversation are ideal. These added bonuses not only move team communication away from email. Additionally, the software, as the primary place for critical updates, encourages even the most resistant to use it regularly.

3. Meetings will not make digital manufacturing innovations mature faster

Teams put too much pressure on meetings. The hope is that a meeting make everything clearer. However, the speed of business has increased and mobile technology constantly breaks members’ focus. Thus, it is time to find supplemental tools to maintain clarity and alignment. Flexible, agile project management software is a great solution that lets you make the most your team at all times. Because these solutions provide multiple views, you can substitute them for powerpoint presentations saving more time.

4. Digital Manufacturing involves partners that must be constantly included

Today, organizations are hiring hundreds of contractorse. Additionally, digital manufacturing initiatives involve a high volume of partners and external consultants. It is absolutely necessary that any key project management solution allows for non-traditional collaboration.

5. Some frameworks support digital manufacturing innovation better

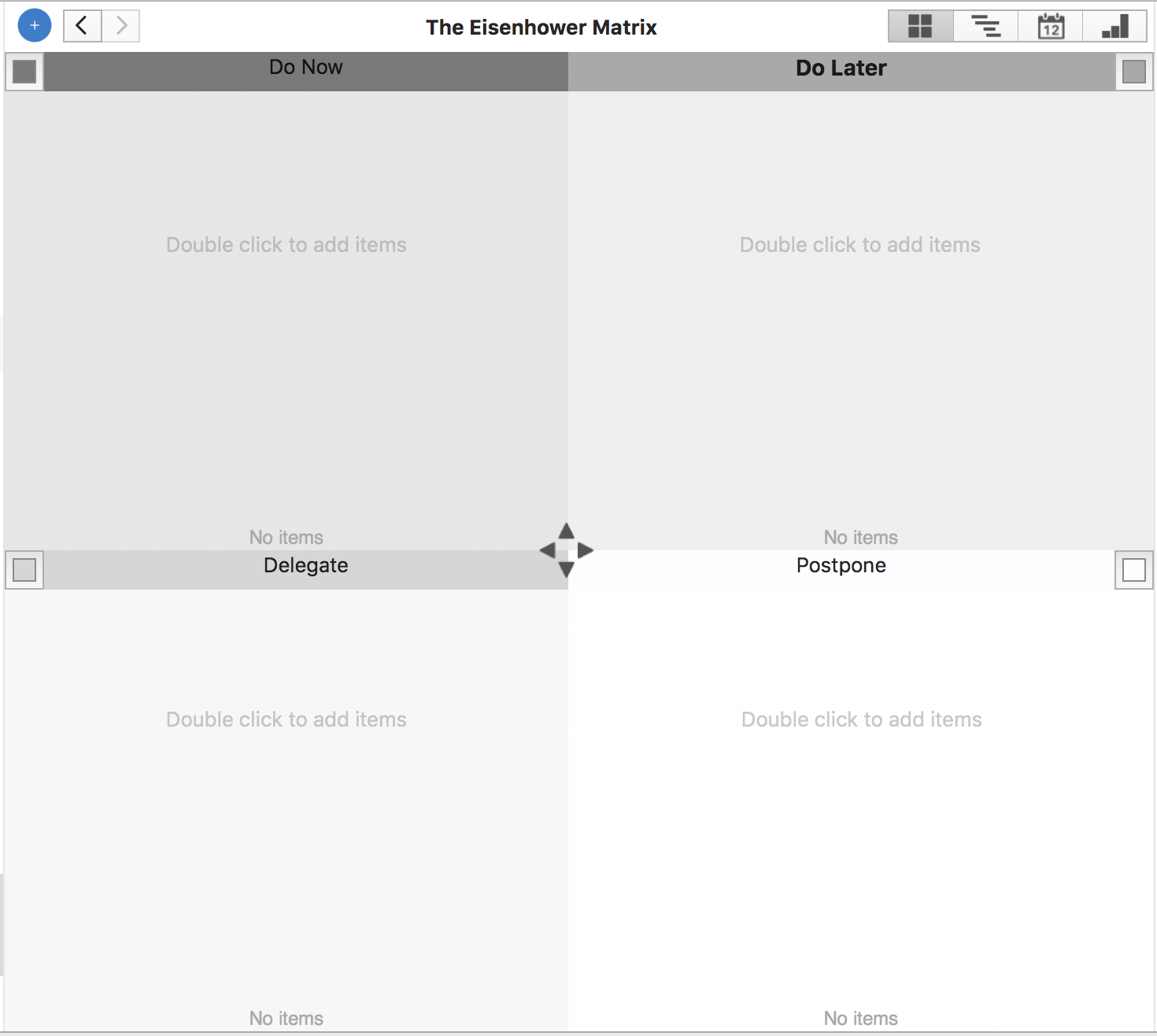

Some frameworks are more effective for visualization and collaboration than others. As an example, the four quadrant framework supports critical initiatives. This is because it clearly defines multiple categories and phases. The Eisenhower Matrix is the most famous four-quadrant framework. Created by Dwight D. Eisenhower, it helps one visualize priority level and make better decisions faster.

Learn more about the Eisenhower Matrix:

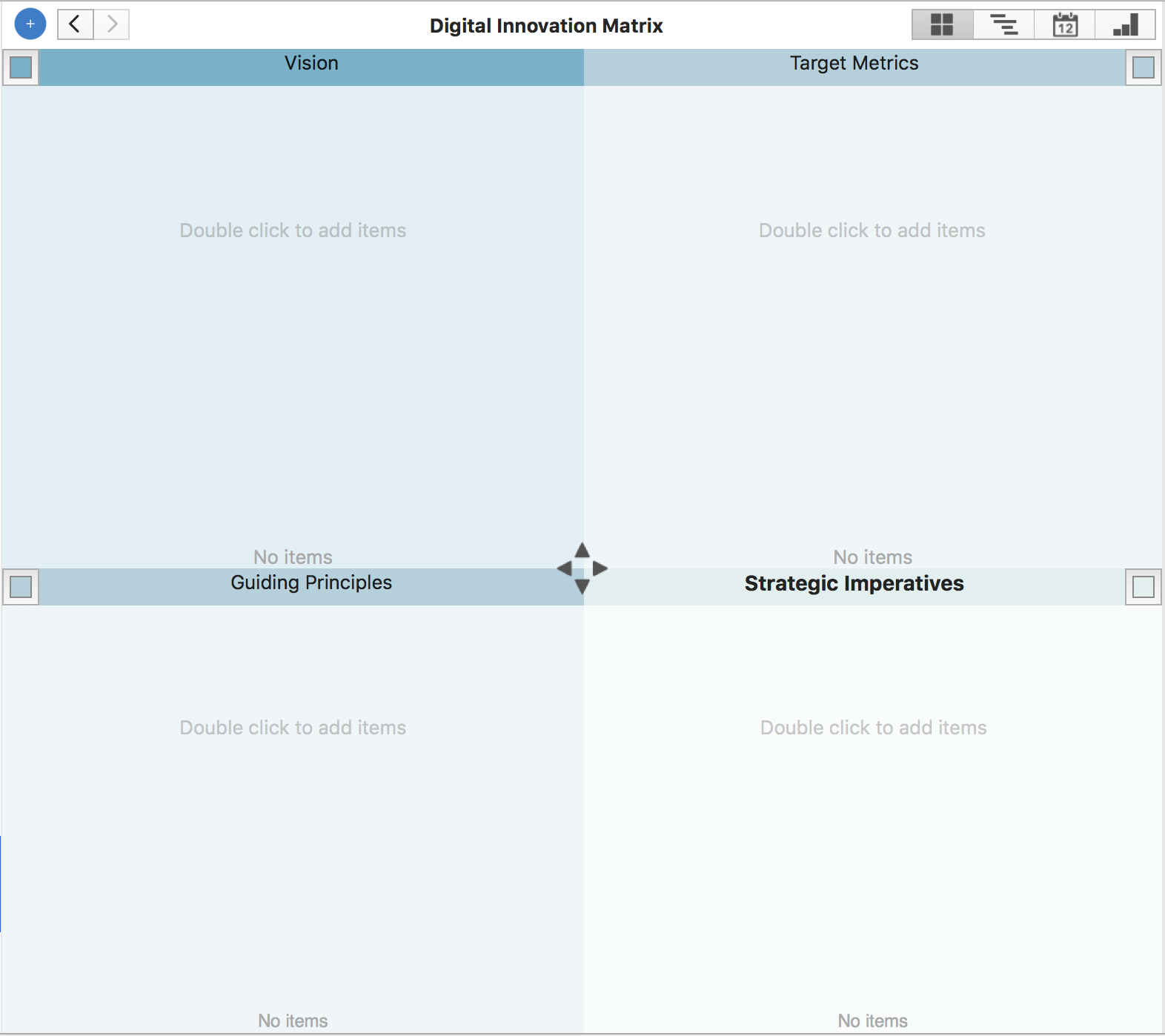

However, one can also customize the 2×2 matrix to better serve individual projects. As an example, the Digital Innovation Matrix, helps executive teams define a clear vision for digital transformation. While this framework helps leadership thoroughly consider their options, it prevents them from getting stuck on this phase for too long or simply starting digital transformation initiatives for the sake of digital transformation alone.

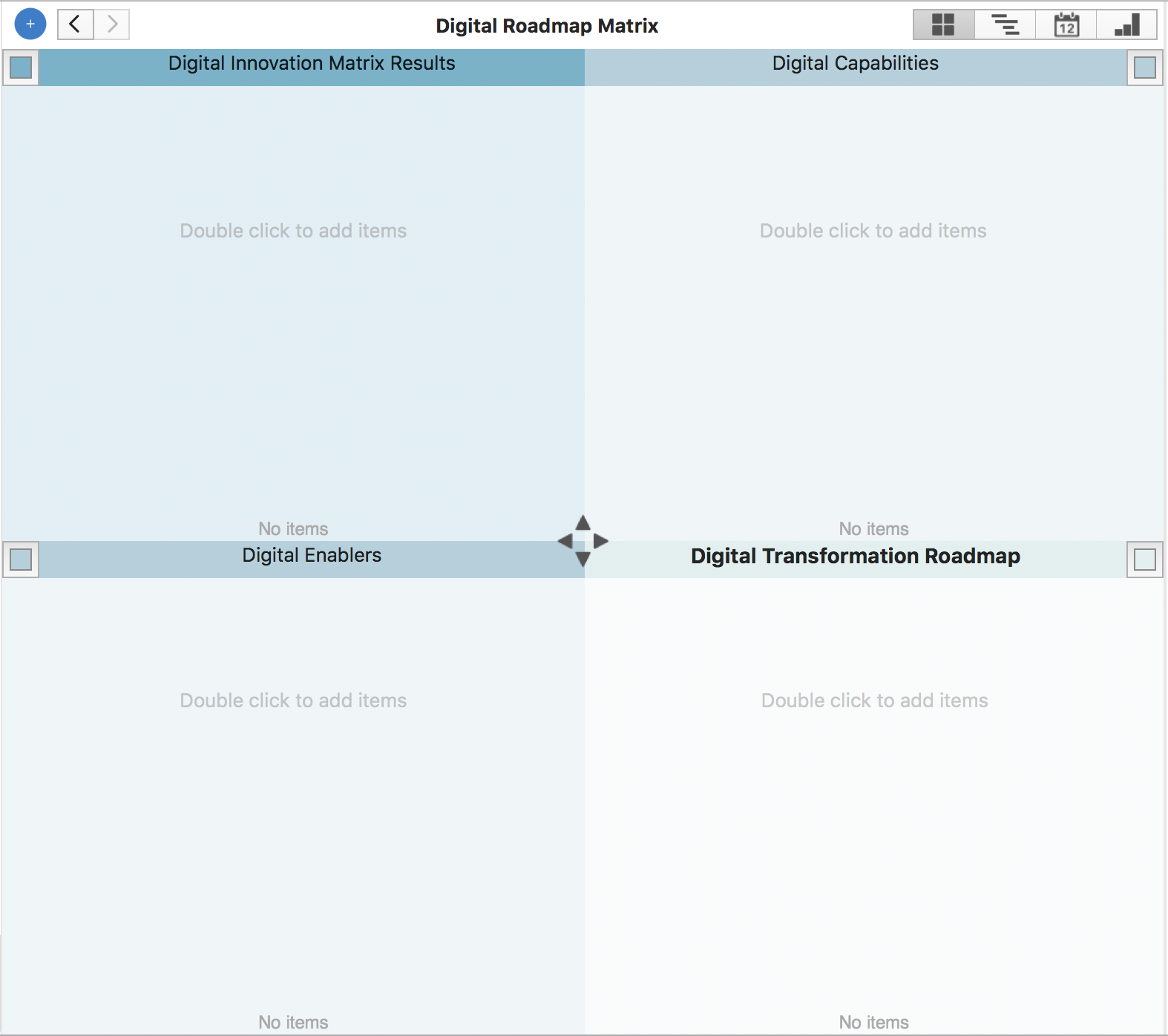

Afterwards, the Digital Roadmap Matrix helps the team move from vision to concrete steps:

Conclusion

Modern collaboration and project management practices like the ones above are prevalent in many industries. The manufacturing industry is an exception. As a first step in digital manufacturing transformation, project visualization and management practices sorely need updating. With great recent leaps in the productivity and collaboration industry, manufacturing teams have the support they need to drive digital manufacturing transformation success.